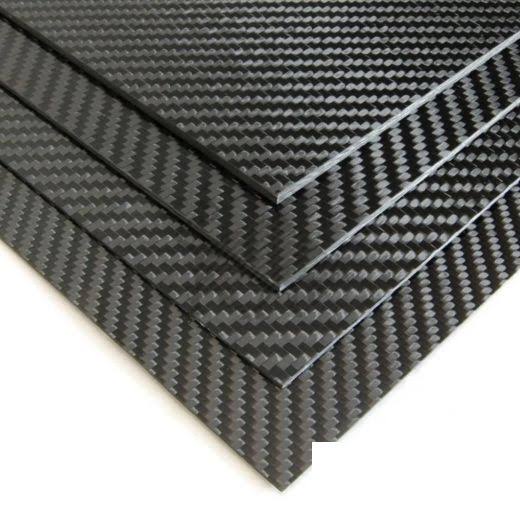

in the ever-evolving world of materials, one innovation has been quietly making waves across various industries: carbon plastic sheets. These innovative materials, crafted from a blend of thermoplastic polymers and carbon fibre reinforcements, offer a unique combination of strength, durability, and lightweight properties that make them indispensable in numerous applications. As industries strive for greater efficiency, sustainability, and aesthetic appeal, carbon plastic sheets have emerged as a game-changing solution, poised to revolutionize the way we design and manufacture products.

The Remarkable Carbon Fiber

at the heart of carbon plastic sheets lies a remarkable material: carbon fiber. Derived from precursor materials like polyacrylonitrile (PAN) or pitch, carbon fiber is renowned for its exceptional tensile strength, stiffness, and resistance to fatigue and corrosion. These properties stem from the material’s unique molecular structure, where tightly-bound carbon atoms form long, parallel chains, resulting in a highly rigid and strong fiber. By expertly integrating these carbon fibers into a thermoplastic matrix, manufacturers create a composite material that harnesses the best qualities of both components. The carbon fibers provide the reinforcing strength and stiffness, while the thermoplastic resin acts as a binding agent, transferring loads between the fibers and providing protection against environmental factors.

Soaring in the Skies

Carbon plastic sheets find widespread use in the aerospace industry, where weight savings translate directly into improved fuel efficiency and reduced environmental impact. Aircraft components like fuselage panels, floor beams, and wing sections increasingly incorporate carbon plastic sheets, contributing to overall aircraft performance and sustainability.The benefits of using carbon plastic sheets in aerospace applications extend beyond weight reduction. These materials also offer superior fatigue resistance, which is crucial for components subjected to repeated cyclic loading during flight. Additionally, their excellent corrosion resistance ensures long-lasting durability, even in harsh environments.

Driving Innovation on the road

automotive industry has also embraced the benefits of carbon plastic sheets. From body panels and interior trim to structural components, these materials offer a potent combination of strength, lightness, and aesthetic appeal. By reducing vehicle weight, carbon plastic sheets contribute to improved fuel efficiency and lower emissions, aligning with the industry’s push toward more environmentally conscious practices. Furthermore, the superior impact resistance of carbon plastic sheets makes them an ideal choice for automotive safety components, such as bumper beams and crash structures. These materials can absorb and dissipate impact energy more effectively than traditional materials, enhancing passenger protection in the event of a collision.

Beauty and Function Combined

Beyond their functional advantages, carbon plastic sheets also boast exceptional aesthetic qualities. Their sleek, modern appearance and versatility in color and texture make them a popular choice for architectural and interior design applications. From eye-catching wall panels and furniture components to decorative accents, carbon plastic sheets add a touch of sophistication and contemporary flair to any space. The ability to mold and shape carbon plastic sheets into intricate designs opens up a world of possibilities for designers and architects. These materials can be used to create unique and visually stunning structures, while still maintaining their structural integrity and durability.

Protective Coatings with Carbon Flair

Another innovative application of carbon-based materials lies in the realm of powder coatings. Carbon powder coatings are a type of protective and decorative finish that combines carbon particles with thermoplastic or thermoset resins. These coatings provide excellent durability, chemical resistance, and aesthetic appeal, making them suitable for a wide range of applications, including automotive components, architectural elements, and industrial equipment. Carbon powder coatings offer several advantages over traditional liquid paint systems. They are free of volatile organic compounds (VOCs), making them more environmentally friendly. Additionally, their superior hardness and abrasion resistance ensure long-lasting protection against wear and tear, minimizing the need for frequent repainting or refinishing.

Sustainability at the Forefront

As industries continue to prioritize sustainability and environmental responsibility, carbon plastic sheets offer a compelling solution. Unlike traditional materials like steel or aluminium, which require energy-intensive extraction and processing methods, carbon plastic sheets can be manufactured using recycled or bio-based materials, reducing their overall carbon footprint. Moreover, the durability and longevity of carbon plastic sheets contribute to a circular economy by minimizing the need for frequent replacements and reducing waste. These materials can often be recycled or repurposed at the end of their lifecycle, further enhancing their environmental credentials.

Endless Possibilities Await

Looking ahead, the potential applications of carbon plastic sheets are vast and ever-expanding. From advanced aerospace and automotive components to cutting-edge consumer electronics and sports equipment, these versatile materials are poised to revolutionize countless industries. In the world of consumer electronics, carbon black plastic masterbatch sheets are being explored for use in lightweight yet durable casings and housings, offering superior protection against drops and impacts. Additionally, their excellent thermal and electrical conductivity properties make them suitable for applications in heat dissipation and electromagnetic shielding. The sporting goods industry is also embracing the benefits of carbon plastic sheets, with manufacturers creating high-performance equipment such as bicycles, golf clubs, and tennis rackets. The combination of strength, lightness, and vibration dampening properties offered by these materials can enhance athlete performance and provide a competitive edge.

Continuous Innovation and Advancement

As research and development efforts continue, we can expect to witness even more innovative applications of carbon plastic sheets. Ongoing advancements in manufacturing processes, material engineering, and additive technologies will undoubtedly unlock new possibilities and push the boundaries of what can be achieved with these remarkable materials. One exciting area of innovation is the development of multi-functional carbon plastic sheets. By incorporating additional components or materials into the composite structure, researchers aim to create materials with enhanced thermal, electrical, or even self-healing properties. These advancements could open up new realms of application in fields such as energy storage, electronics, and smart materials.

The Path to a Sustainable Future

In a world where strength, lightness, and sustainability are paramount, carbon plastic sheets stand as a shining example of human ingenuity and technological progress. By harnessing the power of carbon fibres and expertly blending them with thermoplastic materials, manufacturers have created a material that not only meets the demands of today but also paves the way for a more sustainable and innovative future. As society becomes increasingly conscious of its environmental impact, the adoption of carbon plastic sheets presents a viable solution for reducing energy consumption, greenhouse gas emissions, and waste generation. Their lightweight nature, durability, and recyclability align perfectly with the principles of a circular economy, where resources are maximized, and waste is minimized.

Conclusion

As the world continues to evolve, the demand for high-performance, eco-friendly materials will only grow stronger. Carbon plastic sheets, with their unique blend of properties and sustainability credentials, are well-positioned to meet this demand, ushering in a new era of material innovation and technological progress across a multitude of industries.